New steel grades may require new solutions for welding, including the development of an adapted filler wire. OCAS therefore developed a methodology - via casting, wire rod rolling and drawing - to produce filler wire on lab scale.

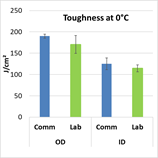

In order to validate the method of producing welding wire on lab scale, a commercially available submerged arc welding wire was reproduced. Both the commercial and the lab processed wire were then used for SAW welding trials.  The good performance of the lab processed wire was confirmed through submerged arc welding experiments performed on a linepipe steel. Two-wire welding was used for inside and outside diameter welding on sheets. The behaviour of the lab wire during welding was similar to that of the commercial wire and no problems were experienced in terms of wire feeding, arc stability or slag removal. When characterising the weld metal, no difference in hardness of the welds was observed and the Charpy impact toughness performance was similar.

The good performance of the lab processed wire was confirmed through submerged arc welding experiments performed on a linepipe steel. Two-wire welding was used for inside and outside diameter welding on sheets. The behaviour of the lab wire during welding was similar to that of the commercial wire and no problems were experienced in terms of wire feeding, arc stability or slag removal. When characterising the weld metal, no difference in hardness of the welds was observed and the Charpy impact toughness performance was similar.

New welding wire for new steel product…

After achieving exceptional corrosion properties on newly developed saline resistant weathering steel, development of a dedicated welding wire was launched. Submerged arc welding wires in different chemistries compatible with the steel were processed and tested in the lab. Excellent toughness and tensile properties could be achieved in the weld metal.

Lab-scale wire processing opens new opportunities for the development of dedicated welding wires for new steel grades, as well as tailored welding solutions for new applications of existing steel grades.

“Lab-scale wire processing will certainly open new opportunities for developing steel grades with new metallurgies and corresponding dedicated welding wires.”

“Without doubt, tailored welding solutions will also bring added value to new applications using existing steel grades.”

“It is exciting to first follow the successful development of a new steel grade, followed by the development of a fully compatible filler wire on lab-scale.”