OCAS has skilled staff and state-of-the art equipment to characterise coated wire, including in-use properties.

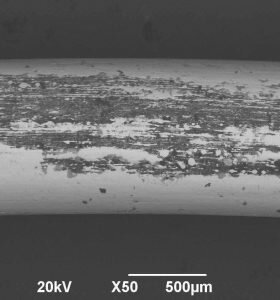

OCAS can evaluate the in-use properties of coated wire such as corrosion resistance, resistance to specific chemicals or corrosive gases, quality of welds, roughness and surface topography, mechanical resistance: hardness, abrasion, friction behaviour, bending, etc.

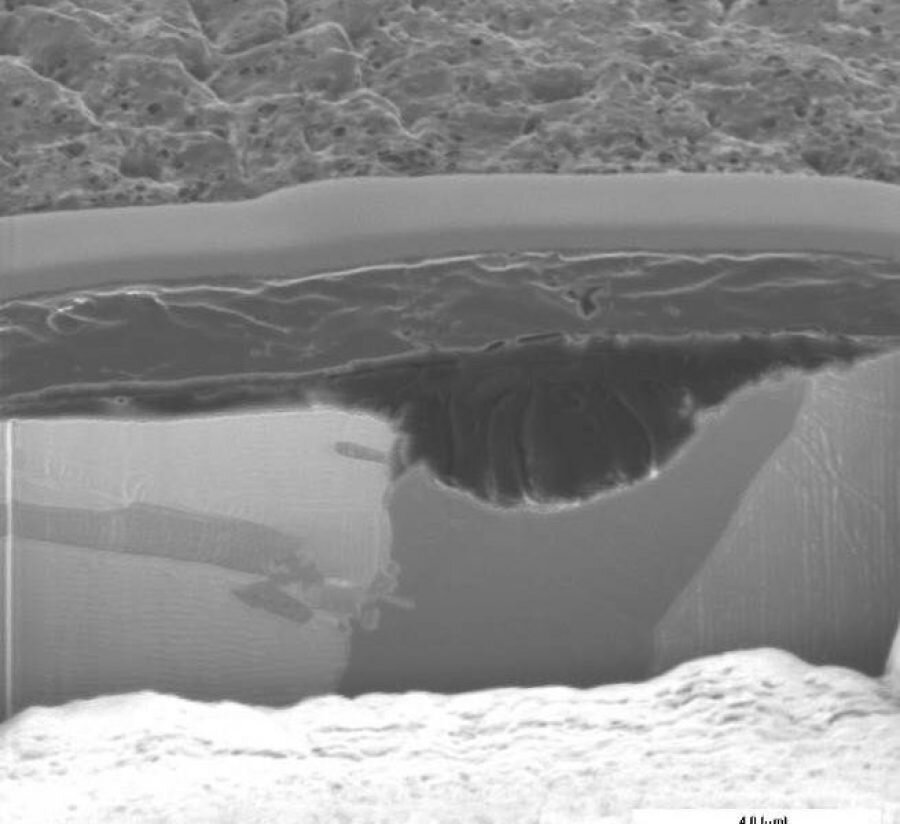

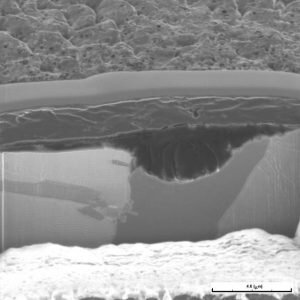

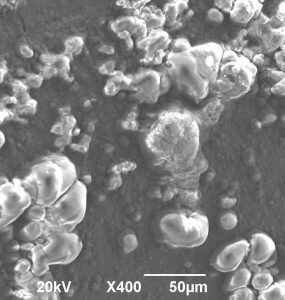

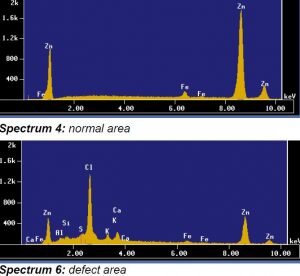

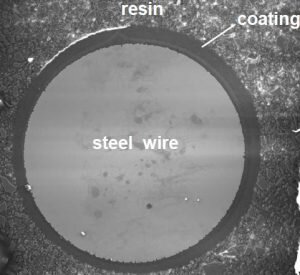

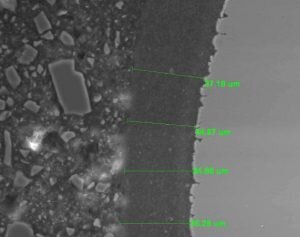

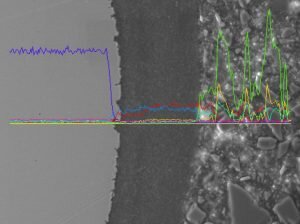

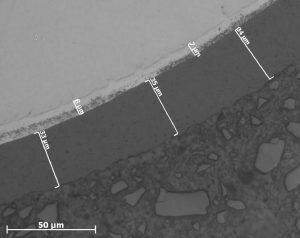

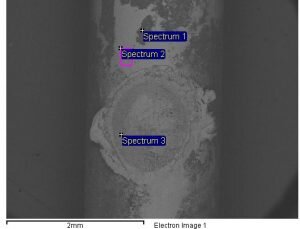

Thanks to our advanced characterisation methods we can furthermore provide problem-solving advice and perform in-depth analysis of wire coating, interface phenomena, adhesion, homogeneity of the coating, etc.

The examples below show some analyses recently carried out:

“Our team combines knowledge on coatings, corrosion, metallurgy and in-use properties. On top of OCAS has the necessary equipment to perform advanced characterisation. A truly unique combination to successfully develop new solutions or optimise existing products”