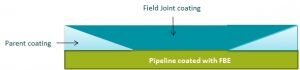

Coated pipes for offshore field joint coatings are submitted to reeling, clamping and field joint application. These processes might induce cracks in the coating due to tensile and shear stress.

OCAS performed extensive material testing to define the limitations of the pipe coating processes under conditions such as reeling, clamping and field joint application.

In order to collect material data that could be used as input for the FEA (finite element analysis), a new test methodology needed to be developed. Non-standard pull-off and lap shear material tests during and after curing of field joint coatings were used.

The methodology was validated by comparing with results from coating samples milled from a field joint pipe section.

Specific parameters could be established for FEA use, enabling to define the limitations of the processes. The new testing methodology allows to study different curing/colling rates in-situ.

Thanks to the data resulting from extensive material testing, the concept was selected by the customer and full-scale testing could be performed to validate this systematic approach.

“Interfacial adhesion strength of field joint materials was determined under tensile and shear stress mode.”