Over the years, OCAS has invested in the knowhow and methodologies to cast High-Entropy and other Compositionally Complex Alloys, a specific class of materials that exhibit great properties. Thanks to these efforts, OCAS today, masters the precise synthesis of tailored compositions in small and larger amounts for a broad range of R&D purposes.

Mastering the processing of ever more complex alloys

Risk-informed alloy design

A vast track record (link to previous case) precedes the competences and capabilities that OCAS has today to estimate the feasibility of a compositionally complex alloy. The tools based on computational thermodynamics, together with return of lab experience, enables OCAS to better predict the feasibility of a novel chemical composition. More information like castability and formability is available at the moment of the alloy design. A crucial stage that benefits from more risk-informed decision making, aiming to reduce costs and gain speeds.

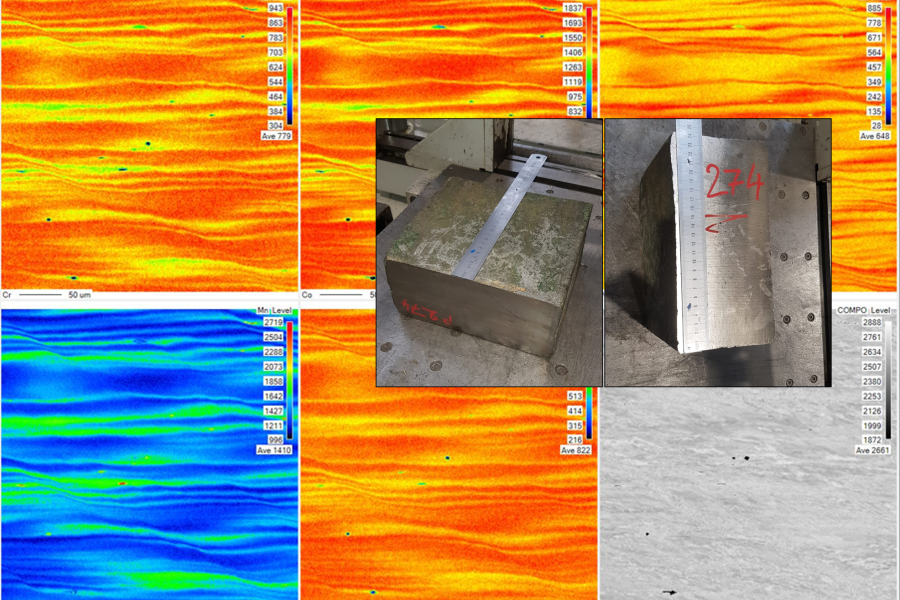

Data-dense material investigation

To meet the endless possibilities and high-dimensional compositional space of HEA and CCA, OCAS tackled this challenge with multidisciplinary and advanced tools. Both from a sample production and a sample processing point of view, efficiency made work reasonable. At OCAS, we have developed custom high-throughput workflows that enable efficient, parallel processing of material samples under lab conditions representative of industrial environments. We have enhanced our sample characterization processes through advanced automation technologies, improving consistency and throughput in our materials (characterisation) labs. Both enhancements result in data-dense material investigation, allowing the power of Artificial Intelligence and Machine Learning to explore correlations between microstructures and properties, solving and understanding the complete PSP relationship in materials.

International partnerships

Recently, OCAS successfully accomplished the collaboration within the international project FORGE. The role of OCAS was the realisation of a ten-fold of unique HEA/CCA of which the material properties then were tested against a series of performance indicators. The investigation aimed to find novel alloy recipes for coatings that exhibit outstanding resilience in harsh environments. Amongst the applications were considered hot and wear exposed components in steel, glass and cement manufacturing industry. The project was supported by the EC, Horizon 2020 framework (Grant agreement 958457).

Future collaborations

OCAS has partnered up with different universities, research centres and leading industries to provide alloys tailored to the needs of the customer. By focussing on our strengths, we contribute to innovation, just by taking care of one small corner stone in large customer research project. We believe in the scientific value that the research on HEA/CCA can bring to material science and for this we target a wide range of industries. As the secrecy of the work is secured under NDA, OCAS becomes a trustful partner in customer projects.

“It was a nice achievement to successfully accomplish the FORGE project. Great to see how our differentiating equipment fosters material science.”

“Joining the strengths in a collaboration with OCAS, we are able to step into the learning curve at higher stage, taking advantage of what we experienced and avoid beginner mistakes”