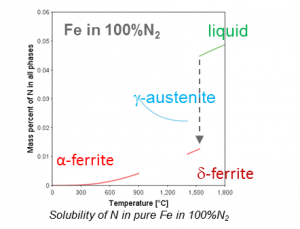

Nitrogen is present in all steels as residual element. In some cases however, nitrogen is wanted and added intentionally as alloying element. Depending on the steel composition, this results in improved performances for specific applications.

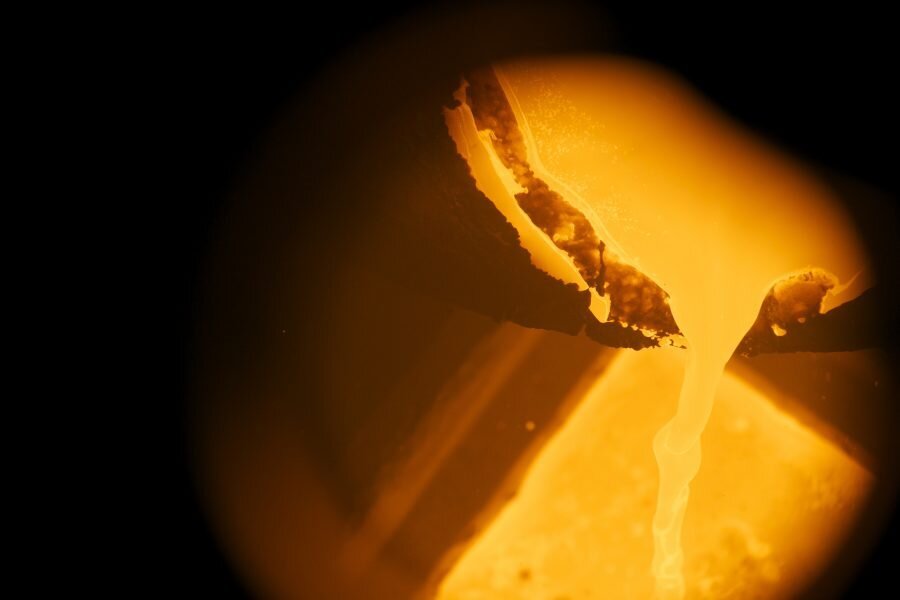

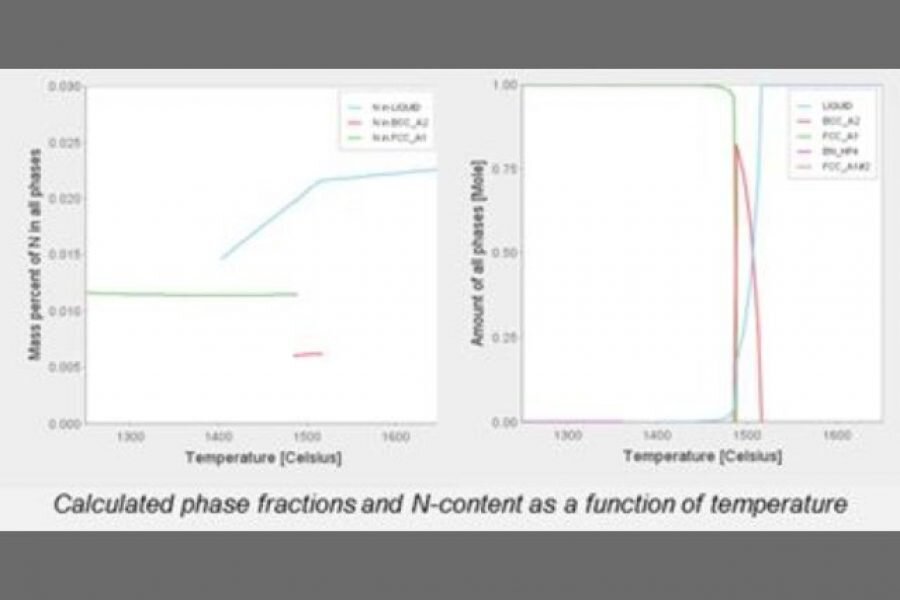

In conventional steel processing, nitrogen alloying is challenging due to its limited solubility during casting and solidification. OCAS developed a methodology to melt, cast and solidify high nitrogen alloys using the laboratory equipment of the Metal Processing Centre, a joint venture of OCAS and CRM. Fundamental knowledge combined with thermodynamic calculations allows OCAS to tailor the nitrogen content of the metal bath and the cast product.

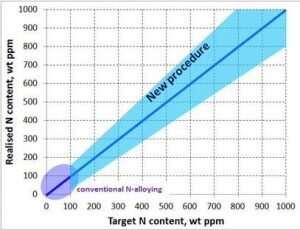

The laboratory equipment allows producing alloys in batches of about 100 kg. Stainless steel grades containing levels up to 500-1000 ppm N have been achieved. For low alloy carbon steel castings with up to 300 ppm nitrogen have already been successfully produced.

In addition to casting, alloys can also be rolled according to customers’ specs. Of course, full characterisation of the samples, including TEM, FIB, and XRD is available at OCAS. Our brand new EPMA will give us additional information thanks to enhanced N characterisation.

The translation of this fundamental knowledge has already proven some interesting tracks, both in liquid and solid phase, which can be tailored to your needs and chemical composition. OCAS is furthermore fully equipped and has the necessary skills to upscale these new lab chemistries to industrial size.

”By carefully selecting and controlling the melting and casting process parameters, we can realize the targeted amount of N in the alloy.”