High-throughput methodologies require flexible equipment to achieve accelerated small scale processing.

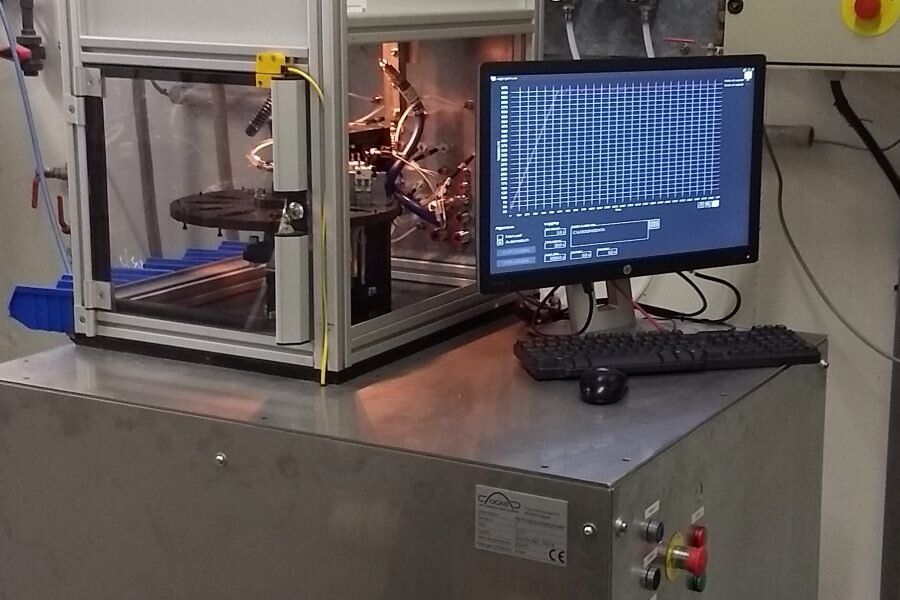

Over the past decade, OCAS invested in new methodologies and equipment for processing and characterisation of miniaturised samples. Recently, the available equipment for high-throughput annealing was complemented with an automated thermal treatment device.

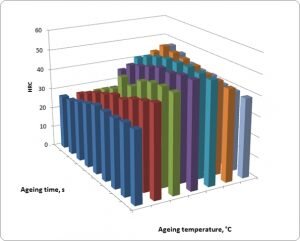

This autonomous euipment takes batches of 12 samples which can be used for thermal treatments from 10 min up to several hours. The samples are ready-to-use for further characterisation (Charpy, tensile test, hardness evaluation, metallography, etc.) making them ideal for exploratory research. The graph below shows hardness Rockwell C results for all tested samples with varying ageing tempearture and ageing time.

Click image to enlarge

Range of high-throughput metal processing equipment

- Small scale casting for rapid screening: 500- 1000 g ingots

- Accelerated rolling enables processing multiple samples rolled in identical conditions

- Box furnaces taking batches of 20-40 samples for homogenisation and tempering treatments, sample size fits for hardness evaluation and metallography/X-ray diffraction

- Autonomous system fo batches of 12 samples, suited for tempering treatments of bars

- Reactive annealing process simulator operating in reactive atmospheres (pure hydrogen, deuterium, amonia, CO2, etc.) in batches of 4 samples including homogeneity check

“This in-house built automated annealing system perfectly complements our range of high-throughput processing equipment.“